SKD11 high wear-resisting ductile general cold work die steel, high carbon high chromium alloy tool steel and vacuum degassing refined steel, steel purity, has good hardenability, quenching deformation small good hardenability.The steel after spheroidizing annealing softening, machinability is good, the carbide particles small even, do not need to worry about the quenching crack strengthening elements molybdenum and vanadium are joined.

High hardness, high wear resistant uniform eutectic carbides, good toughness, not easy craze, > 62 HRC hardness after quenching.At 525 ℃ nitriding processing time for 20 h/h/h, 60 ammoniation layer depth of 0.25 mm / 0. 30 mm / 0. 35 mm, the surface hardness is 1250 hv,At 570 ℃ nitriding processing time is 2 h, nitriding depth 10 ~ 20 microns, the surface hardness is 950 hv.

Si ≤0.40

Mn ≤0.60

P ≤0.030

S ≤0.030

Cr 11.0-13.0

Mo 0.80-1.20

Ni ≤0.50

V 0.20-0.50

Cu ≤0.25

X165CrMoV12 Cold working die steel

Quick Details

SKD11 high wear-resisting ductile general cold work die steel, high carbon high chromium alloy tool steel and vacuum degassing refined steel

Delivery

- Delivery status: Hot-Rolled 、Forged 、

- Surface: Blank 、Polished 、Peeled 、

- Standard: JIS

- Shape: Round, Flat, Square, Hexagon, Plate, Sheet, Other

Inventory Status

| Product type | Products | Dimension | Processes |

|---|---|---|---|

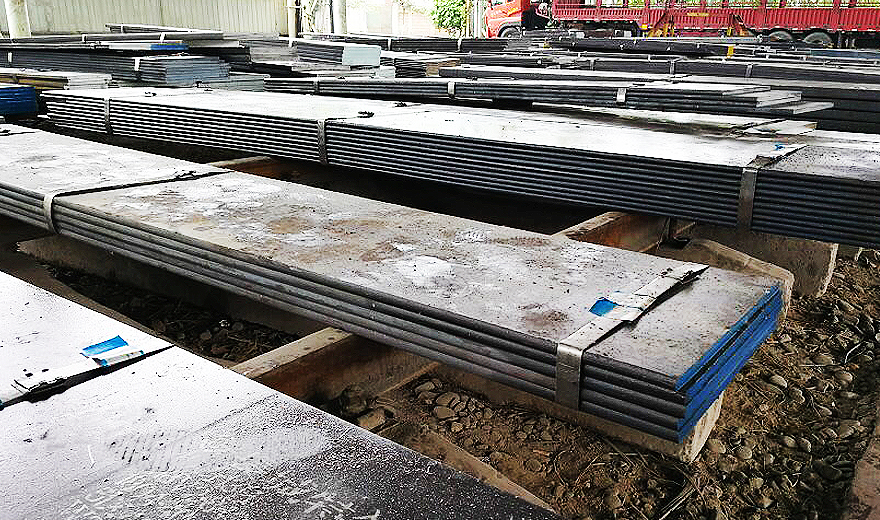

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled |

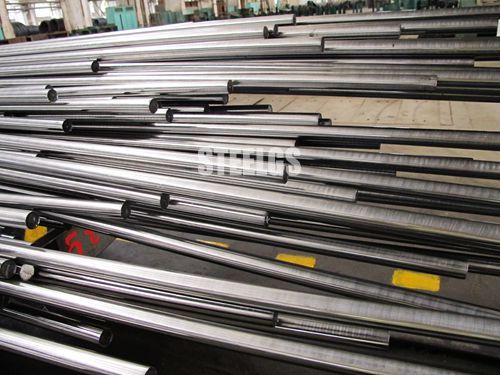

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded |

Product Details

Related Products

- Previous: SKD-11 Cold working die steel

- Next: D2 Round Bar

- Enquiry

- Print this page