Category

- Tool Die Steels

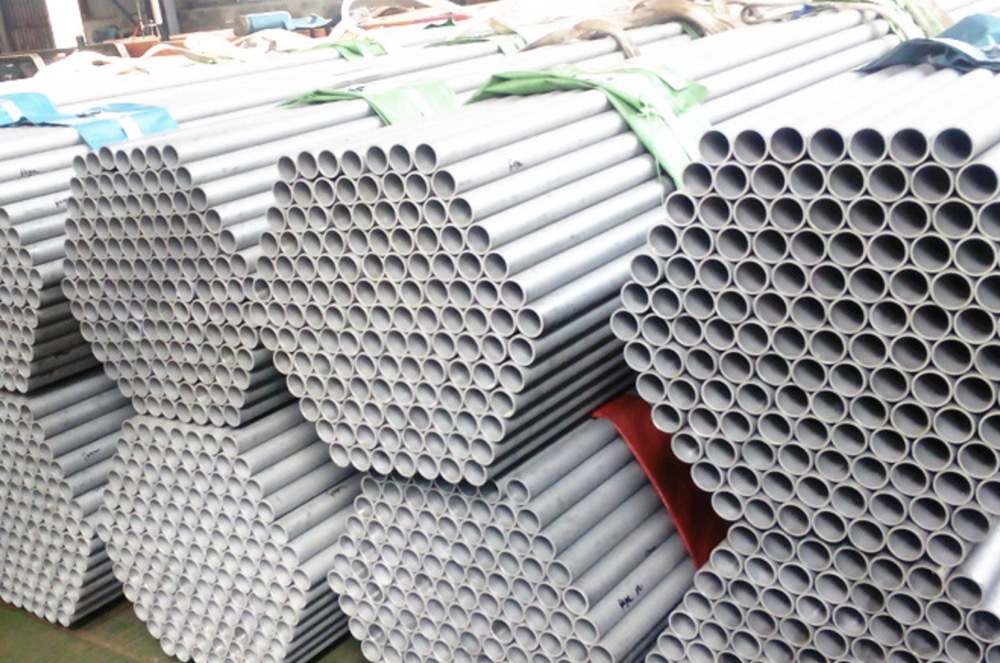

- Stainless Steels

- Structural Steel

- Cast Iron and Cast Steel

- Superalloys

- Special Alloy

- Aviation and Aero Steel

- Maraging steel

- Boiler, Pressure Vessel Plates, Alloy Steel, Chromium-Molybdenum

Contact

+86-13880247006

E-mail: sales@longhaisteel.com